Pinkerton’s Distillery

The Art of Distillation

In the heart of Lubbock, Texas, Pinkerton’s Distillery awaits those with a taste for exceptional spirits. Born from the passion and dedication of Lucas Pinkerton, Pinkerton’s Distillery is a testament to the art of distillation.

The Story

Lucas, a Lubbock native and self-taught master distiller, embarked on his journey into the world of alcohol production at a young age, brewing his own beer as a teenager.

“I was introduced to making beer when I was 19 and Lubbock was a dry town,” Lucas said. “I saw the process and was like, ‘Oh I can do that,’ so I went to the store and bought all the ingredients. The first little bit was rocky, but I finally figured it out.”

As Lucas progressed, he started making wines and eventually, his curiosity led him to the intricate world of distillation. In 2014, Lucas was finishing his last year at Texas Tech University before graduating with a business degree. Upon graduating, he poured all his focus into getting his business up and running, along with building “Betsy” (his beloved pot still) from the ground up.

“When I was looking at opening this up, I looked at the market and craft stuff at the time was not huge,” Lucas said. “I wanted to do something I loved so I decided to start with rum.”

In mid-2015, Lucas launched Pinkerton’s Distillery with the platinum rum. The coconut and gold rum followed soon after in 2017. Then in 2019, “Betsy” got an upgrade to produce vodka. Lucas then started producing premium vodka which would soon be the base for the Burn Vodka and the Apple Burn Vodka.

“When I was making rum, I was trying to sell it to all the bars so I hit up Dustin Six at the Blue Light,” Lucas said. “About the third time I went in there, he had me try some vodka that he had been putting peppers in. I thought it was very interesting and we decided to collaborate to make this habanero-infused vodka.”

After an extensive amount of research, Lucas developed a way to extract the flavors from the habanero peppers to add to his premium vodka to create the famous Burn Vodka Lubbockites know and love. According to Jeremy Jones, one of Pinkerton’s Distillery partners, Pinkerton’s is the only distillery in the country that mixes flavored vodka in the bottle.

Coming into 2020, the distillery was at an all-time high as Lucas had “patched together distribution across the state and contracted a state-wide distributor.” However, COVID hit and Lucas had to pivot to keep the distillery alive.

“We survived COVID by making hand sanitizer, giving away 90% to first responders,” Lucas said. “I was struggling at the time to do it all alone and couldn’t expand or grow the business by myself. So eventually, I approached some very good friends that were looking to do a startup of their own and we decided to go in together to make this go further.”

Today, Pinkerton’s Distillery is comprised of six partners: Lucas Pinkerton, Jeremy Jones, Neal Turner, Justin Kotarski, Duane Preskey and Kenny Grant.

“Me and the other partners handle the business side of the distillery including marketing, sales and partnerships,” Jeremy said. “This frees Lucas up to focus on making a quality product and he is really good at that.”

Pinkerton’s products are sold in many of Lubbock’s favorite liquor stores and bars including Shotgun Sue’s, The Blue Light Live, Pinkies, Specs and Ollie’s.

The Process

Fermentation

Fermentation marks the initial stage in crafting both rum and vodka. When making rum, Lucas seeks out high-sugar American molasses, which is referred to as “Heavy Brix.” Molasses is naturally fermentable, so all Lucas has to do is dilute it before introducing the yeast. This process results in fermentation over 9-10 days, leading to alcohol volumes ranging from 11% to 13%.

As for vodka production, Lucas utilizes food-grade yellow corn grown in the Texas panhandle. He pulverizes the corn into a fine flour and then converts it to fermentable sugar through a mashing process, similar to cooking a baked potato to transform starch into sugar. Finally, the yeast is introduced and the mixture ferments for approximately 7-9 days. Lucas says that he will process anywhere between 3-6,000 pounds of corn at a time.

Distillation & Aging

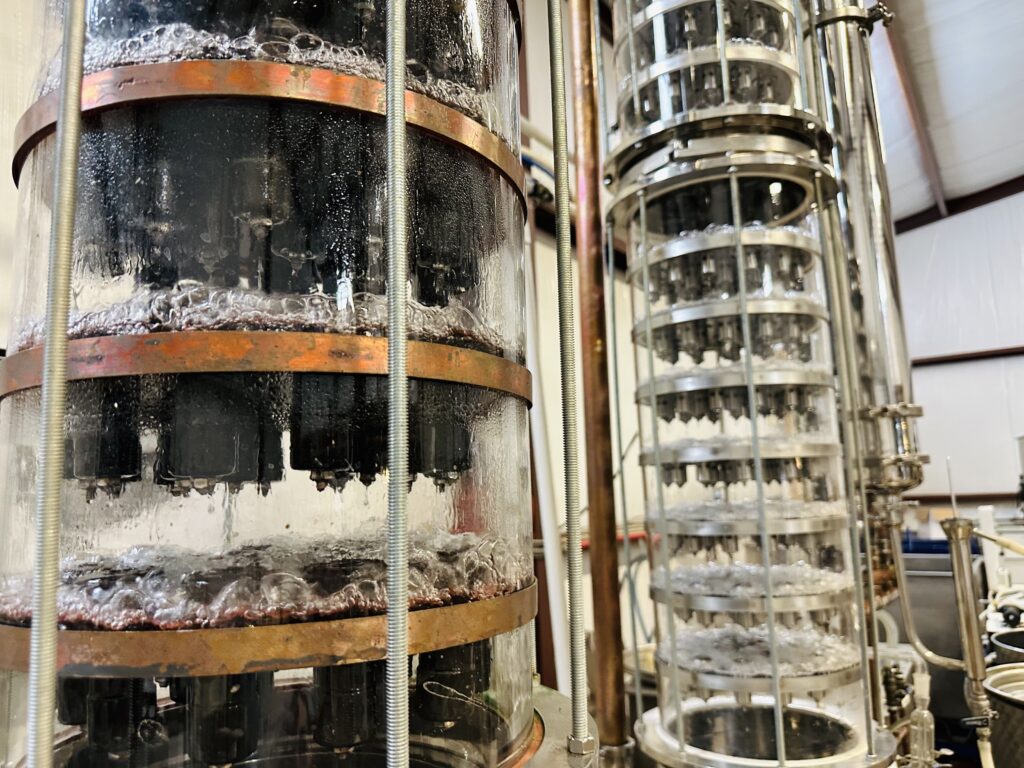

The distillation process for both rum and vodka occurs in Lucas’s beloved pot still, “Betsy.” “Betsy” is comprised of a refluxing pot that is connected to two columns of trays, one made of copper and one made of stainless steel. For vodka, the finished ferments are added to the refluxing pot, where it is heated to a boiling point. It then turns into a vapor that ascends upwards through the copper column and then the stainless steel column which contains a total of 21 trays. These trays serve as a crucial filtration system, refining the alcohol while separating it from other compounds. As the vapor rises, it begins to bubble and has to re-distill to go to the next tray. The result is an alcohol content starting at about 10-12% above volume within the pot and exiting at 190-191 proof, translating to roughly 95-96% alcohol. Vodka undergoes two distillation cycles, ensuring a superior end product. The meticulous process aims to mimic nature’s water cycle, controlling the environment to create an exceptionally pure liquid. The liquid moves from the pot to the copper column, channels into a basin and then flows up through another column, where it is condensed back into a liquid form.

On the other hand, for rum production, a different approach is taken to retain the spirit’s distinct flavor profile. Here, a single copper column is utilized, as the goal is to avoid over-distillation and instead emphasize the rum’s character. Copper plays a vital role in the process by extracting sulfates. This highlights the versatility of Pinkerton’s Distillery, where each spirit is crafted with a unique distillation method tailored to preserve its distinctive qualities, resulting in a range of exceptional products for consumers to enjoy.

The next step in the process is aging. To create gold rum, Lucas ages the rum with oak infusion spirals. These spirals are made of the same materials as a classic oak barrel and dropped directly in the pit after distillation. The rum then pulls the sugars from the oak into the rum making it have a gold color. These spirals allow Lucas to control the flavor profile of the rum more than with a barrel, as barrels take time to mature and each contains a different flavor profile

Dilution & Bottling:

At Pinkerton’s Distillery, precision and expertise are key in crafting their exceptional spirits. Both rum and vodka are diluted down to 80 proof, ensuring the optimal balance of flavor and strength. This meticulous process involves a precise calculation of water addition based on the known proof of the high-proof distillate and the weight of water, allowing them to achieve the desired proof.

Maintaining strict quality control, Pinkerton’s Distillery conducts final proofing with hydrometers, adhering to a narrow variance of just 0.3 to ensure accuracy and safety. Once the spirits are perfectly proofed, they are efficiently prepared for bottling. Utilizing a 4-step bottle filler, they can process up to 700 bottles per hour. The bottles are meticulously cleaned and inspected before labeling and packaging.

Infusion

The last step of the process is infusion. To create coconut rum, Lucas adds a coconut flavor and just enough sugar to excite the coconut flavor. This results in a flavored rum that is 7 calories per shot.

For the Burn Vodka, Lucas sources habanero peppers grown from all over the United States to create a habanero extract that he injects into the premium vodka. This process takes about a day to complete. From here, Lucas can then inject apple extract to create the Apple Burn. This is a cocktail in a bottle that mimics a candy apple with a habanero kick.

Why Pinkerton’s

Pinkerton’s Disterlly has distinguished itself from other distilleries in Texas through its commitment to crafting exceptional products, garnering numerous prestigious awards.

“Our products are made 100% from scratch here in Lubbock, Texas so by proxy we produce a pure Texas product,” Jeremy said. “Almost none of the other ‘Texas vodkas’ are actually made in Texas. Many companies are buying vodka from somewhere else, mostly Kansas, and just running it through a distill.”

Lucas Pinkerton’s words, “Taste it, it will speak for itself,” resonate with the brand’s ethos. Their dedication to creating outstanding products, made with care and precision right in Lubbock, doesn’t go unnoticed. As they continue to expand and innovate, Pinkerton’s Distillery aims to further share their passion for exceptional spirits with an even wider audience, all while staying true to their roots and celebrating the support of their valued customers.

To learn more about local businesses and products made in Lubbock, Texas, follow @lubbockeda on all platforms, and check out our blog page here.

“Anyone can come to Lubbock for half of a day and see what type of culture this community is about.”

Christopher Fisher

VXI Global Solutions

-

Josh Jung’s Home Base | Lubbock, Texas

Read more: Josh Jung’s Home Base | Lubbock, Texas -

South Plains College’s Drone Program: Shaping the Future of Aviation

Read more: South Plains College’s Drone Program: Shaping the Future of Aviation -

Quality of life is unmatched in Lubbock, Texas

Read more: Quality of life is unmatched in Lubbock, Texas -

EL ROBI | Empowering Futures Through Skilled Trades in Lubbock, Texas: The City of Opportunities

Read more: EL ROBI | Empowering Futures Through Skilled Trades in Lubbock, Texas: The City of Opportunities -

Texas Invests in the Future: What the $20B Water Fund Means for Lubbock and the State

Read more: Texas Invests in the Future: What the $20B Water Fund Means for Lubbock and the State -

POV: It’s Time to Move to Lubbock, Texas — Parade of Homes Edition

Read more: POV: It’s Time to Move to Lubbock, Texas — Parade of Homes Edition